| Availability: | |

|---|---|

| Quantity: | |

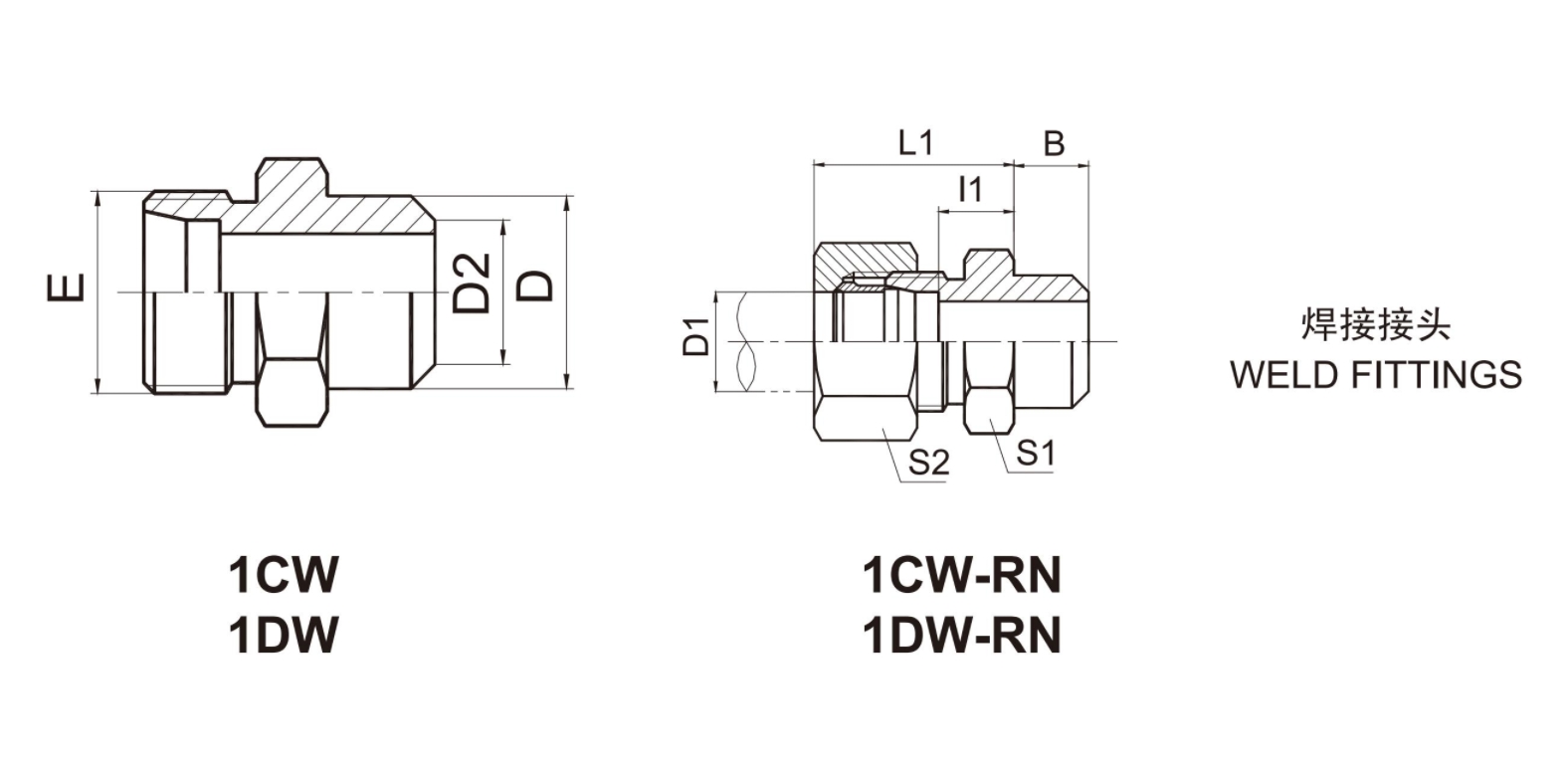

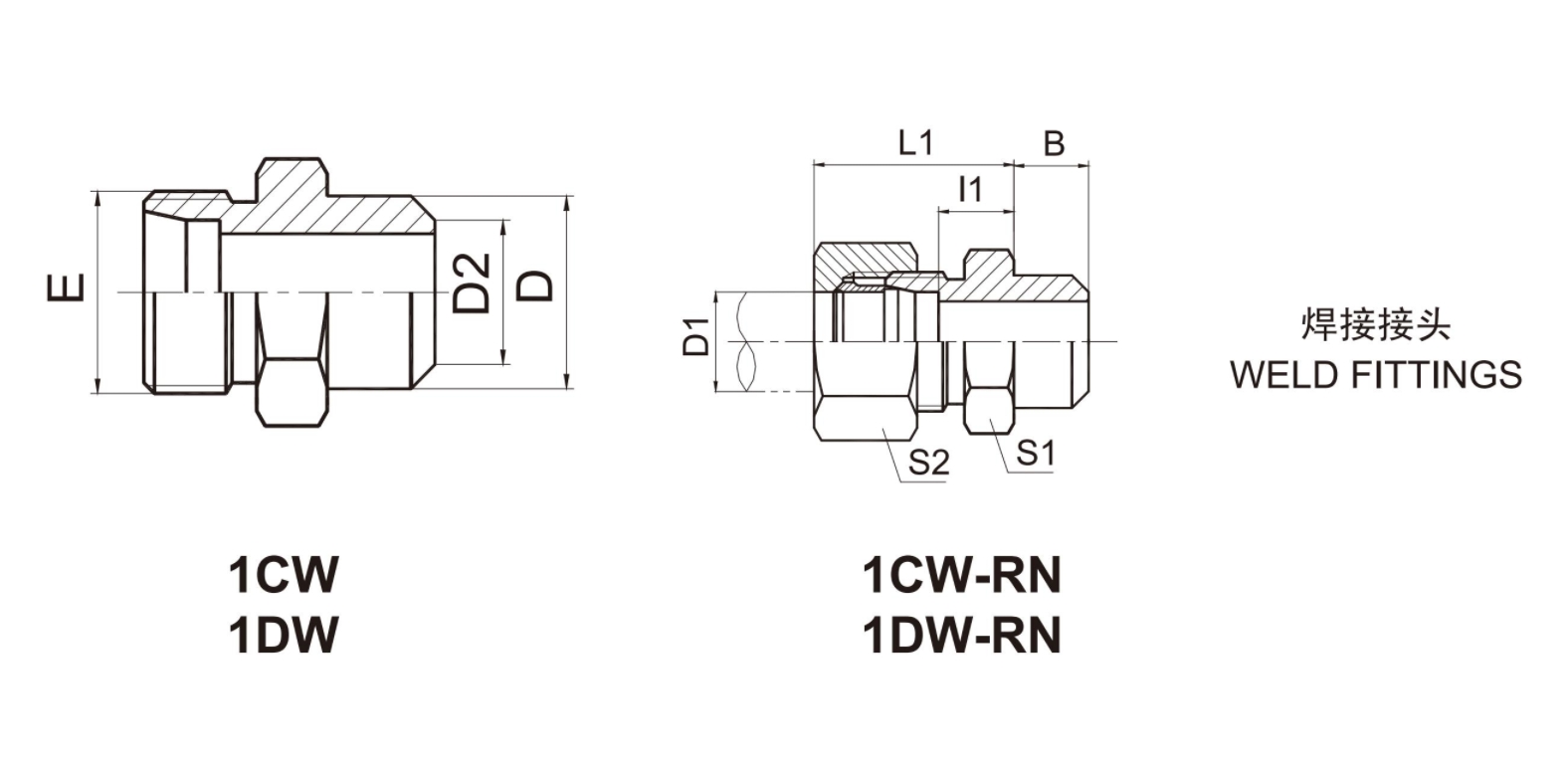

1CW/1DW fittings are specialized hydraulic adapters engineered for secure, permanent connections between hydraulic hoses and pipes, featuring a weld-on male end and metric bite-type connection. Designed to comply with DIN 2353 standards, they integrate a male metric thread with a 24° cone seal on one end for leak-tight tube attachment, while the other end is welded to bulkheads or system components for structural stability.

Crafted from durable carbon steel or stainless steel, these fittings often receive zinc plating to enhance corrosion resistance, suiting harsh industrial environments. Available in straight, bulkhead, and other styles, they cater to diverse installation needs—with the "-RN" suffix indicating complete sets inclusive of a cutting ring and nut for ready assembly.

Ideal for hydraulic systems requiring permanent, high-pressure connections (rated up to 31.5MPa), they excel in applications where disassembly is unnecessary. By combining standardized compatibility, robust welded construction, and reliable bite-type sealing, 1CW/1DW fittings ensure efficient fluid transfer across manufacturing, construction, and automotive hydraulic setups, embodying durability and practicality for critical system integrations.

| PART NO. | THREAD | TUBE O.D. | DIMENSIONS | MPa | |||||||

| E | D1 | D2 | B | D | I1 | L1 | S1 | S2 | |||

| 1CW-12-06 | M12x1.5 | 6 | 6 | 7 | 10 | 7 | 22 | 12 | 14 | 31.5 L series | |

| 1CW-14-08 | M14x1.5 | 8 | 8 | 8 | 12 | 8 | 23 | 14 | 17 | ||

| 1CW-16-10 | M16x1.5 | 10 | 10 | 8 | 14 | 9 | 24 | 17 | 19 | ||

| 1CW-18-12 | M18x1.5 | 12 | 12 | 8 | 16 | 10 | 25 | 19 | 22 | ||

| 1CW-22-15 | M22x1.5 | 15 | 15 | 10 | 19 | 11 | 26 | 22 | 27 | ||

| 1CW-26-18 | M26X1.5 | 18 | 18 | 10 | 22 | 11.5 | 28 | 27 | 32 | ||

| 1CW-26-22 | M26X1.5 | 18 | 22 | 10 | 27 | 13.5 | 28 | 27 | 32 | 16 L series | |

| 1CW-30-22 | M30x2 | 22 | 22 | 12 | 27 | 13.5 | 30 | 32 | 36 | ||

| 1CW-30-25 | M30x2 | 22 | 25 | 12 | 31 | 13.5 | 30 | 32 | 36 | ||

| 1CW-36-28 | M36x2 | 28 | 28 | 12 | 32 | 16.5 | 33 | 38 | 41 | ||

| 1CW-45-35 | M45X2 | 35 | 35 | 14 | 40 | 14.5 | 36 | 46 | 50 | ||

| 1CW-52-42 | M52X2 | 42 | 42 | 16 | 46 | 16 | 39 | 55 | 60 | ||

| 1DW-14-06 | M14x1.5 | 6 | 6 | 7 | 11 | 11 | 26 | 14 | 17 | 63 S series | |

| 1DW-16-08 | M16x1.5 | 8 | 8 | 8 | 13 | 13 | 28 | 17 | 19 | ||

| 1DW-18-10 | M18x1.5 | 10 | 10 | 8 | 15 | 12.5 | 29 | 19 | 22 | ||

| 1DW-20-12 | M20x1.5 | 12 | 12 | 10 | 17 | 14.5 | 31 | 22 | 24 | ||

| 1DW-22-14 | M22x1.5 | 14 | 14 | 10 | 19 | 16 | 34 | 24 | 27 | ||

| 1DW-24-16 | M24x1.5 | 16 | 16 | 10 | 21 | 15.5 | 34 | 27 | 30 | 40 S series | |

| 1DW-30-20 | M30x2 | 20 | 20 | 12 | 26 | 17.5 | 39 | 32 | 36 | ||

| 1DW-36-25 | M36x2 | 25 | 25 | 12 | 31 | 20 | 44 | 41 | 46 | ||

| 1DW-42-30 | M42x2 | 30 | 30 | 14 | 36 | 20.5 | 47 | 46 | 50 | ||

| 1DW-52-38 | M52X2 | 38 | 38 | 16 | 44 | 23 | 54 | 55 | 60 | 31.5 S series | |

| Note:In case if you are interested to order the adapter in complete set with cutting ring and nut it is necessary to insert suffix "RN"after our part no.,for example 1CW-30-22RN. | |||||||||||

1CW/1DW fittings are specialized hydraulic adapters engineered for secure, permanent connections between hydraulic hoses and pipes, featuring a weld-on male end and metric bite-type connection. Designed to comply with DIN 2353 standards, they integrate a male metric thread with a 24° cone seal on one end for leak-tight tube attachment, while the other end is welded to bulkheads or system components for structural stability.

Crafted from durable carbon steel or stainless steel, these fittings often receive zinc plating to enhance corrosion resistance, suiting harsh industrial environments. Available in straight, bulkhead, and other styles, they cater to diverse installation needs—with the "-RN" suffix indicating complete sets inclusive of a cutting ring and nut for ready assembly.

Ideal for hydraulic systems requiring permanent, high-pressure connections (rated up to 31.5MPa), they excel in applications where disassembly is unnecessary. By combining standardized compatibility, robust welded construction, and reliable bite-type sealing, 1CW/1DW fittings ensure efficient fluid transfer across manufacturing, construction, and automotive hydraulic setups, embodying durability and practicality for critical system integrations.

| PART NO. | THREAD | TUBE O.D. | DIMENSIONS | MPa | |||||||

| E | D1 | D2 | B | D | I1 | L1 | S1 | S2 | |||

| 1CW-12-06 | M12x1.5 | 6 | 6 | 7 | 10 | 7 | 22 | 12 | 14 | 31.5 L series | |

| 1CW-14-08 | M14x1.5 | 8 | 8 | 8 | 12 | 8 | 23 | 14 | 17 | ||

| 1CW-16-10 | M16x1.5 | 10 | 10 | 8 | 14 | 9 | 24 | 17 | 19 | ||

| 1CW-18-12 | M18x1.5 | 12 | 12 | 8 | 16 | 10 | 25 | 19 | 22 | ||

| 1CW-22-15 | M22x1.5 | 15 | 15 | 10 | 19 | 11 | 26 | 22 | 27 | ||

| 1CW-26-18 | M26X1.5 | 18 | 18 | 10 | 22 | 11.5 | 28 | 27 | 32 | ||

| 1CW-26-22 | M26X1.5 | 18 | 22 | 10 | 27 | 13.5 | 28 | 27 | 32 | 16 L series | |

| 1CW-30-22 | M30x2 | 22 | 22 | 12 | 27 | 13.5 | 30 | 32 | 36 | ||

| 1CW-30-25 | M30x2 | 22 | 25 | 12 | 31 | 13.5 | 30 | 32 | 36 | ||

| 1CW-36-28 | M36x2 | 28 | 28 | 12 | 32 | 16.5 | 33 | 38 | 41 | ||

| 1CW-45-35 | M45X2 | 35 | 35 | 14 | 40 | 14.5 | 36 | 46 | 50 | ||

| 1CW-52-42 | M52X2 | 42 | 42 | 16 | 46 | 16 | 39 | 55 | 60 | ||

| 1DW-14-06 | M14x1.5 | 6 | 6 | 7 | 11 | 11 | 26 | 14 | 17 | 63 S series | |

| 1DW-16-08 | M16x1.5 | 8 | 8 | 8 | 13 | 13 | 28 | 17 | 19 | ||

| 1DW-18-10 | M18x1.5 | 10 | 10 | 8 | 15 | 12.5 | 29 | 19 | 22 | ||

| 1DW-20-12 | M20x1.5 | 12 | 12 | 10 | 17 | 14.5 | 31 | 22 | 24 | ||

| 1DW-22-14 | M22x1.5 | 14 | 14 | 10 | 19 | 16 | 34 | 24 | 27 | ||

| 1DW-24-16 | M24x1.5 | 16 | 16 | 10 | 21 | 15.5 | 34 | 27 | 30 | 40 S series | |

| 1DW-30-20 | M30x2 | 20 | 20 | 12 | 26 | 17.5 | 39 | 32 | 36 | ||

| 1DW-36-25 | M36x2 | 25 | 25 | 12 | 31 | 20 | 44 | 41 | 46 | ||

| 1DW-42-30 | M42x2 | 30 | 30 | 14 | 36 | 20.5 | 47 | 46 | 50 | ||

| 1DW-52-38 | M52X2 | 38 | 38 | 16 | 44 | 23 | 54 | 55 | 60 | 31.5 S series | |

| Note:In case if you are interested to order the adapter in complete set with cutting ring and nut it is necessary to insert suffix "RN"after our part no.,for example 1CW-30-22RN. | |||||||||||