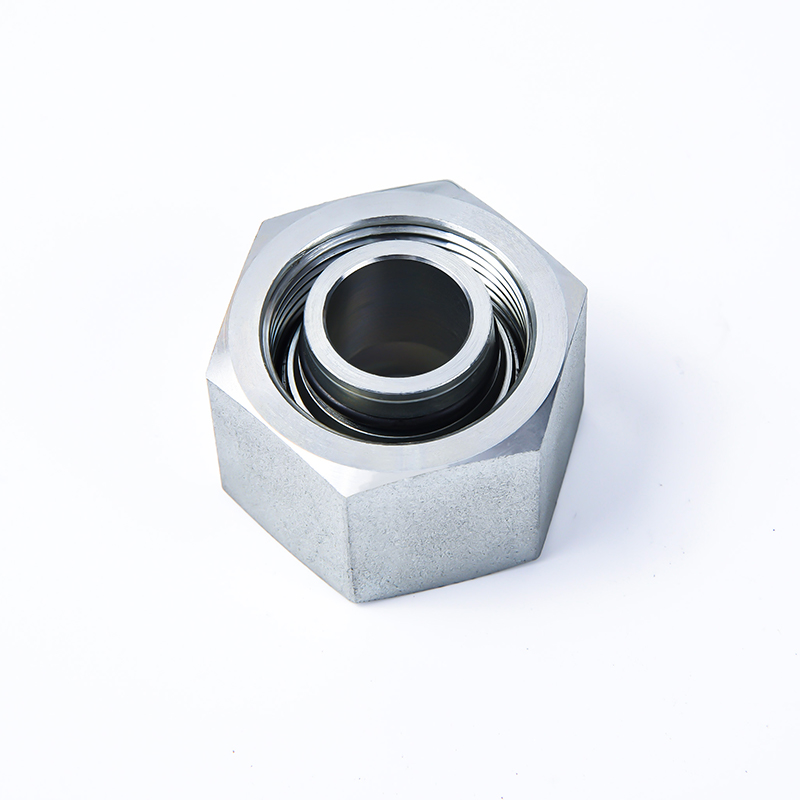

The American thread right angle adjustable joint is a key connection component widely used in industrial systems. Its design combines the characteristics of American JIC thread and adjustable SAE thread, and has good sealing, stability, adjustability and wide applicability.

The American thread right angle adjustable joint adopts O-ring sealing structure to ensure good sealing performance under high pressure and high temperature environment. The O-ring fits tightly with the sealing surface through its elastic deformation to form an effective sealing barrier to prevent fluid leakage. This sealing method is very reliable in industrial applications, especially for systems that require long-term stable operation.

For some models, the product adopts a metal interference sealing structure of spherical surface to conical surface. This structure uses the taper design of the thread to make the thread produce a larger contact area and pressure when tightening, thereby improving the sealing effect. During the tightening process, the thread can slide a certain distance to avoid damage to the sealing surface due to overtightening. The contact pressure between the sealing surfaces is uniform, which helps to improve the sealing reliability. Avoid excessive local pressure and reduce wear and fatigue of the sealing surface. The longer contact area of the sealing surface helps to improve the sealing effect.

The product is made of AISI 316L stainless steel, which has excellent corrosion resistance and is suitable for a variety of industrial environments, including high temperature, high pressure, corrosive media, etc. Its structural design is reasonable and precision machining technology is used to ensure high matching accuracy between components, reducing sealing failure or loose connection caused by assembly errors.

The product has a sturdy structure and good vibration and shock resistance, suitable for dynamic load environments. In industrial systems, equipment is often subjected to vibration and shock. The product can effectively resist these external forces and ensure the stability and reliability of the connection.

The product complies with international standards such as ISO 11926, ISO 8434-2, SAE J514, etc., to ensure its stable performance in different application scenarios. These standards have strict requirements on sealing, material properties, manufacturing processes, etc., and products that meet the standards are more reliable in practical applications.

The product is an adjustable design, suitable for connection requirements at different angles, such as 90° elbows, tees, etc. This design not only improves the convenience of installation, but also enhances the adaptability and flexibility of the system. Users can adjust the angle of the joint according to actual needs to adapt to complex pipeline layouts.

The product supports a variety of connection methods, including American JIC threads, SAE threads, flanges, etc., to meet different system requirements. This multi-interface design makes the product compatible with different industrial systems and easy to integrate with other equipment and systems.

The product is widely used in hydraulic systems, pneumatic systems and hybrid systems, and can withstand pressures up to 420 bar. Its structural design takes into account high temperature, high pressure, vibration resistance and shock resistance, and is suitable for dynamic load environments.

EN

EN  中文简体

中文简体