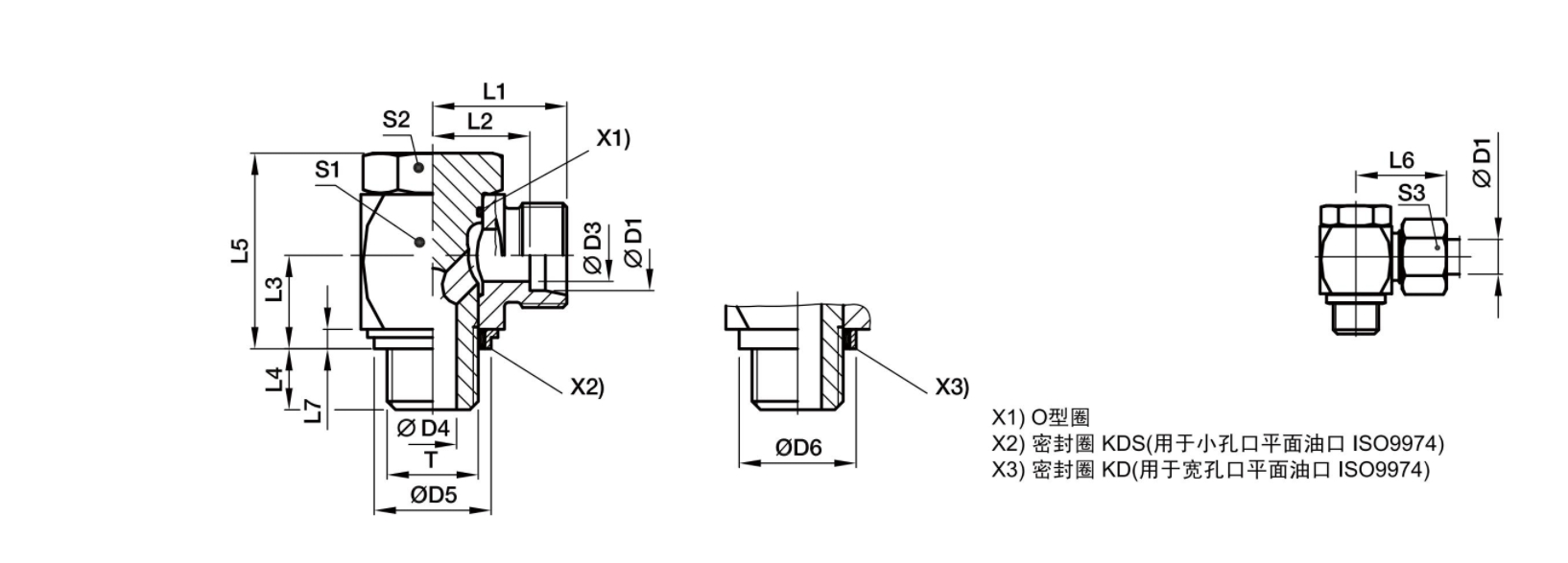

1CI 1DI-M WH-M-KDS high pressure articulated coupling, metric threaded elastomeric seal, metric male threaded female tapered 24° taper on one end for forming to the pipe end, welded pipe, ferrule connection, metric threaded (ISO 9974) articulated bolt, non-throttled eccentric flow path design, with soft seal E type KDS ring. Pressure range up to 420 bar/6000 PSI, international standard: DIN2353 3861/ISO8434, available in standard pipe diameters 24° cone light connection (DIN2353)06L-42L, 24° cone heavy connection (DIN2353)06S-38S.